We specialise in Selective Laser Sintering (SLS) and the machines involved in the process are very high end and require a detailed knowledge of 3D printing to use.

An SLS printer deposits a layer of SLS Nylon powder and uses a laser to set the layer in place. Then it lays another layer of powder, sets it and repeats.

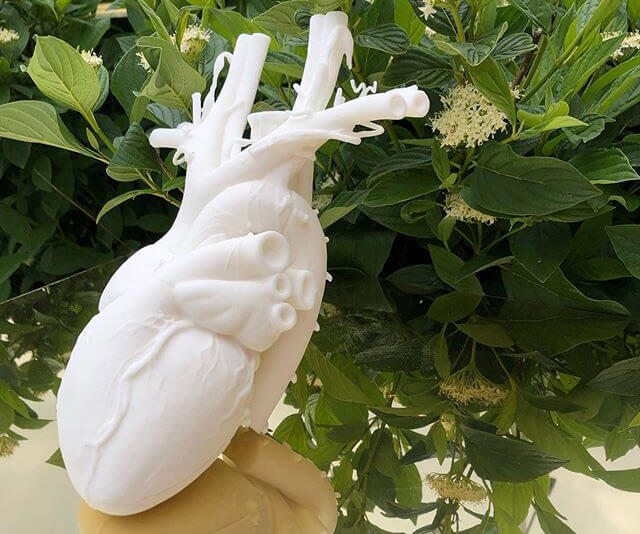

The nylon itself is an incredibly strong and versatile material that can produce very fine details compared to other types of 3D printing.

The finish is also superior, as the laser melts the layers together. This produces a far smoother finish than other print types, and results in far less work during the latter more labour orientated stages of production.

One of the main advantages of the SLS print process over other processes is that it can print objects without the need for additional supports.

This allows designs to include very complex shapes and pieces .

OUR SLS 3D PRINTER SPECIFICATIONS

Maximum Build Size

350mm x 300mm x 450mm

Production Time

Depending on our workload and the exact requirements of your brief, our SLS turnaround is 2-4 working days.

The easiest way to submit your job to us is by sending your files to us with a description of finishes etc and we will respond swiftly with a quote and any artwork advisories we may notice.

OUR “READY FOR PRINT ” VOLUMES

As a reference, we have created a volume pricing guide below.

For competent designers, these prove useful to get a quick idea of cost from us before submitting artwork and saves some of the less creative discussion.

For those less experienced in 3D printing, they give you a good education into the expected financial brackets of 3D SLS printing.

Despite providing these guides, we do urge our customers to submit all art files for detailed quote.

We pride ourselves on attention to detail and will, most likely, save you a lot of time effort and money by inspecting all the details of print.

*All Prices are subject to VAT

SLS Nylon Ready to Print Volumes Guidelines.

- Make sure the parts do not exceed the stated volume.

- Make full use of your volume through tessellated stacking but ensure you leave a minimum of 2mm between each part.

- We clean every 3D printed volume with air and, for larger pieces, with sand for cleaning.

- Please bear in mind that our volumes may need additional powder cleaning on receipt and small pieces are often supplied in sliceable cages.

Use Our Online Pricing Tool to Get a Quote

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.